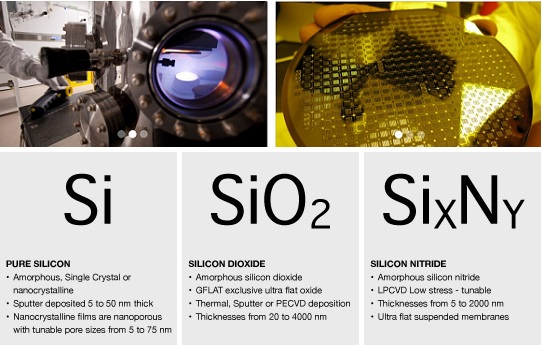

カスタムグリッド

| Si PURE SILICON | SiO SILICON NITRIDE | SiN SILICON OXIDE |

| ●アモルファス, 単結晶, ナノ結晶シリコン ●スパッタ-蒸着 5~50nm膜 ●ナノ結晶フィルムの微細孔 ポアサイズ5~75 nm |

●アモルファス酸化シリコン ●GFLATウルトラフラット膜 ●サーマル, スパッターまたは PECVD蒸着 ●膜厚: 20~4000 nm |

●アモルファス窒化シリコン ●LPCVD低ストレス ●膜厚:5~1000 nm ●ウルトラフラット メンブレン |

カスタムグリッド作製ワークフロー

① 仕様打合せ

② クロムマスクデザイン/プリント

③ Si, SiNまたはSiO 蒸着

④ パタンーニング/エッチング

⑤ 光学, SEM検査

■ SILICON WAFER SPECIFICATIONS

-100, 200, 300 um thick and standard thicknesses

100 & 200um thickness: 100 mm (4-inch) diameter wafer

310um thickness: 150 mm (6-inch) diameter wafer

■ CUSTOM MASK DESIGN AND CHROME MASK PRINTING

-Feature size resolution to 350 nanometers (line/space resolution).

-Minimum membrane window size typically ~5 microns.

-Maximum membrane window size (based on film) up to 25 mm x 25 mm.

■ FRONT-TO-BACK ALIGNMENT LITHOGRAPHY

-Front-to-back tolerance +/-5 microns or better (+/-20 microns for 150mm).

-Features as small as 500 nanometer circles can be etched in suspended membranes.

-Orientation or identification marks can be etched into suspended membrane or over support silicon

to reduce interference with imaging.

■ METAL DEPOSITION

-Deposition of aluminum, palladium, gold, 50 to 200 nm thicknesses

-Deposition of adhesive layer of titanium, chrome, etc.

-Features to less than 10 microns with alignment to membrane windows within +/-5 microns.

■ DEVICE PACKAGING

-Devices are typically separated from the supporting wafer and packaged in transparent gel-boxes

for ease of handling and viewing.

-All devices are individually inspected under light microscopy.

-Devices can also be designed with continuous films for spin coating that can be later dissected

along scribe lines by the customer.

会社概要

会社概要